Exploring Different Types of Sheet Metal Bending

When manipulating metal, there are several processes you need to consider for optimal workflow. Bending your sheet metal is one of these processes, and there are many ways to go about it. Exploring different types of sheet metal bending allows you to understand the best method for various projects, making the most efficient use of your fabrication processes.

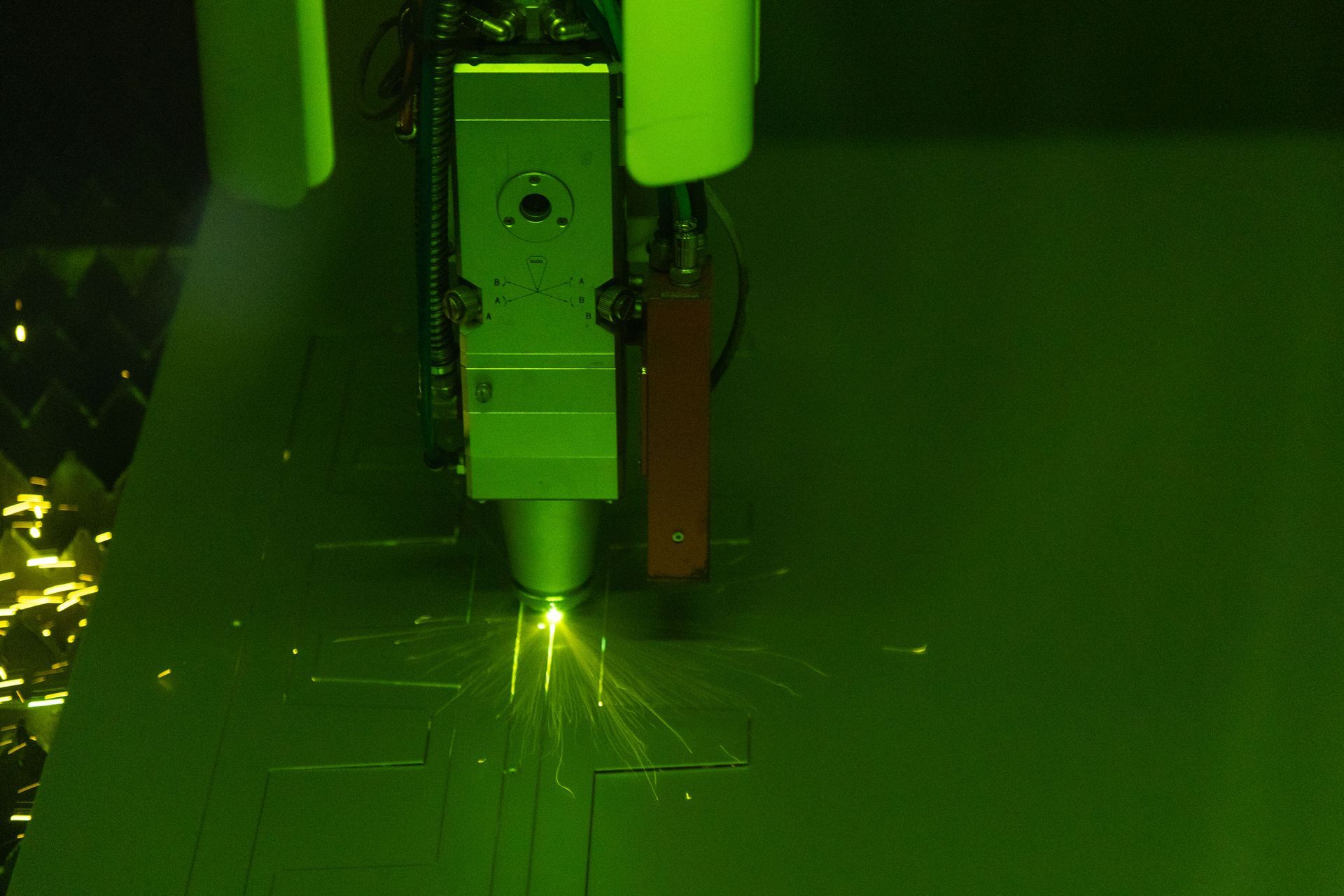

Air Bending

With air bending, your metal sheet only touches your punch’s tip and your die’s sides. The die can be either V-shaped or square-shaped. The punch forces the metal to conform to your die, offering a quick and easy method for bending.

Air bending ranks among the most common methods that fabrication shops utilize, but it can come at the cost of precision. This drawback comes from the metal not making complete contact with the die, allowing the metal to potentially bend out of shape.

Folding

Folding is another widespread technique metal fabricators employ. The process requires the metalworker to attach clamping beams to the longer sides of their sheet metal.

The beams then rise and fold the sheet around a bending profile, manipulating the metal into the preferred shape. There are several crucial components to the folding process. However, metalworkers can largely automate the process due to the relative ease of folding.

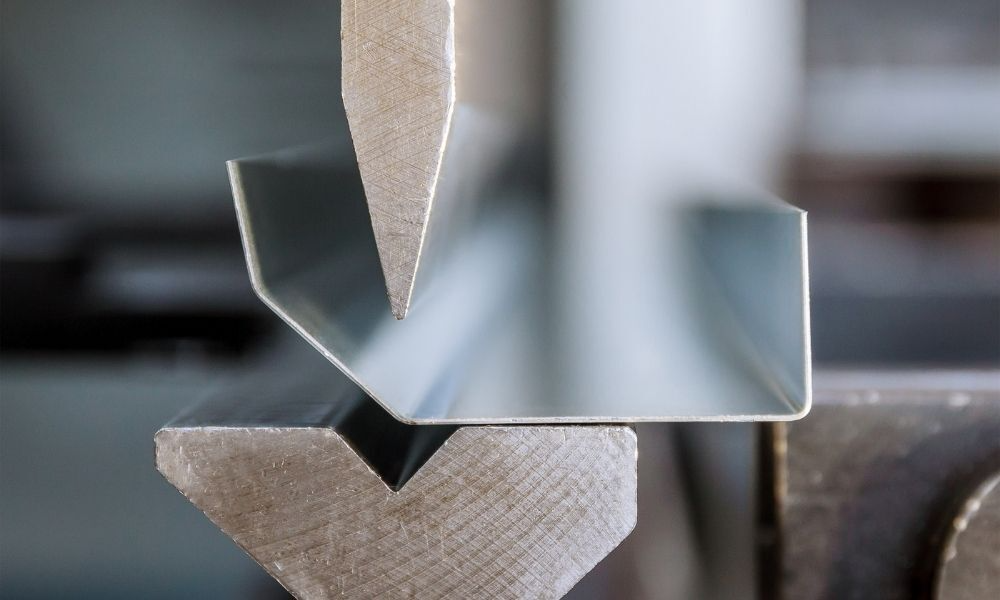

Coining

Like air bending, coining punches sheets into a die, forming the metal folds. But the main difference with coining is that it utilizes substantially more power than air bending. It uses 5 to 30 times the pressure of air bending. Thus, coining produces little to no spring back in the metal, providing high precision.

Although coining allows for more power and fidelity, it is an expensive process—far more so than air bending. This makes coining more uncommon among metalworkers who favor cheaper processes, even if they sacrifice some precision.

Know Best Practices

When you need to make the most of your bending processes, you should understand different types of sheet metal bending methods. Often, fabrication shops don’t provide all the necessary work themselves, as it’s cheaper to seek third-part assistance than keeping everything in-house. Know what you can reliably accomplish, and always be aware of what sheet metal bending services you need to utilize to create a better product.