How ASF’s New Laser Cutting Capability Improves Turnaround in 2026 Projects

Architectural System Fabricators continues to invest in the latest technology to support faster, more precise metal fabrication. With the addition of a state-of-the-art laser cutting machine in 2026, ASF expands its ability to meet tight deadlines while maintaining high quality standards. Learn how laser cutting helps speed up production timelines and supports complex architectural projects.

Faster Fabrication Without Compromising Quality

Laser cutting uses a focused beam of light to melt, burn, or vaporize metal with high precision. This allows ASF to cut a wide range of metals at high speed without the need for extensive secondary processing.

Compared to mechanical cutting methods, laser cutting creates cleaner edges and tighter tolerances. This reduces the need for additional finishing and helps parts move quickly to the next step in the fabrication process.

Better Accuracy for Complex Designs

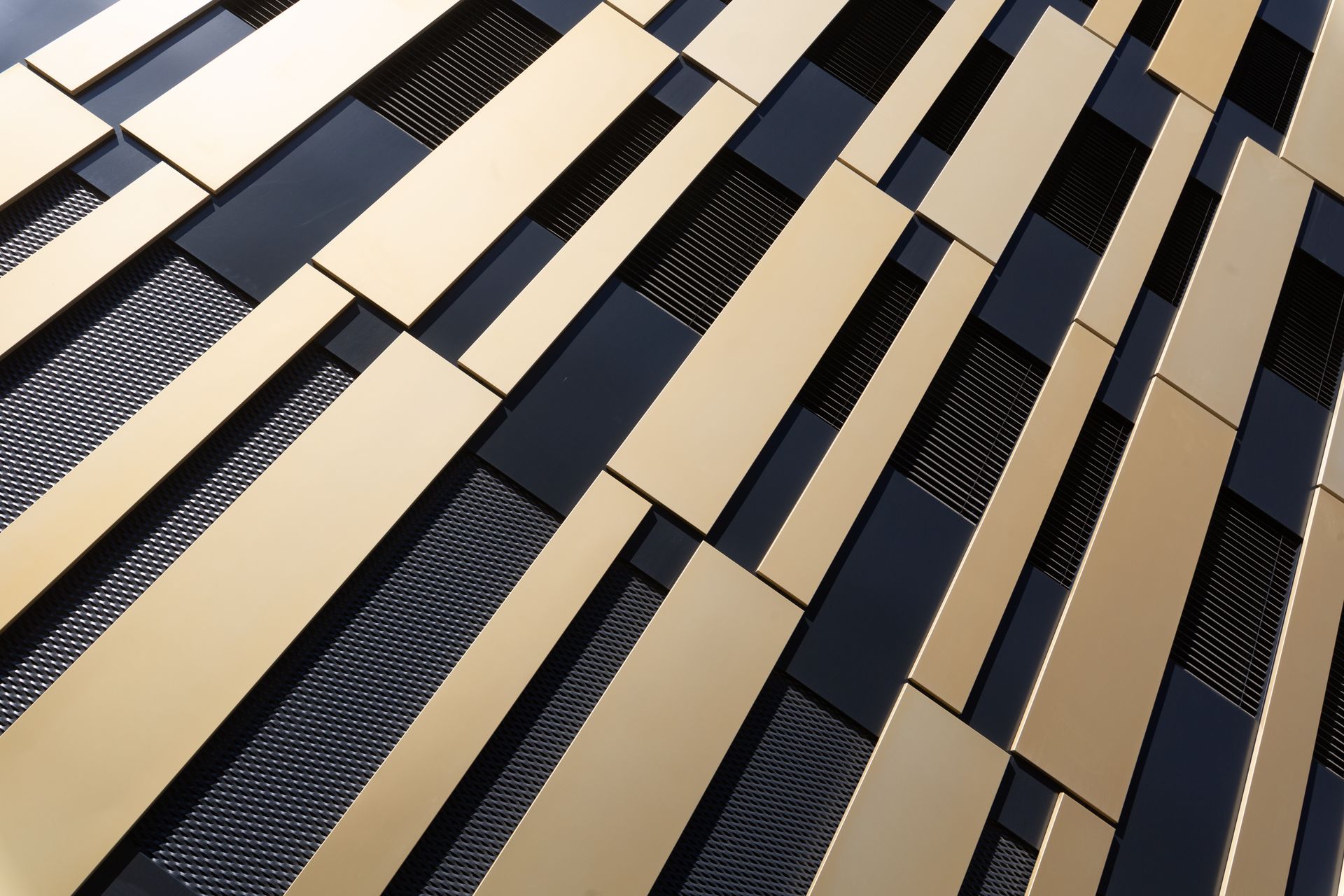

Modern architectural components often require intricate cuts, tight curves, or detailed openings. Laser cutting makes it easier to produce these designs consistently and accurately. ASF can now handle complex profiles and patterns directly from digital drawings, reducing manual labor and increasing repeatability.

This capability is especially useful for contractors and architects working with ACM panels, custom profiles, screen walls, and decorative metalwork.

Supports Short Lead Times

Deadlines are a constant pressure on commercial construction projects. With the new laser cutting machine in-house, ASF reduces turnaround time by eliminating the need to outsource precision cutting. This gives ASF more control over production schedules and helps avoid delays caused by third-party vendors.

Customers benefit from a faster overall process, especially when paired with ASF’s other in-house services like brake forming, coil processing, and CNC routing.

Compatible With a Range of Metals

ASF’s laser cutting machine can process a variety of materials used in architectural metal fabrication, including aluminum, steel, stainless steel, and more. This flexibility allows for consistent quality across different product lines, whether for roofing, wall panels, trim components, or custom fabrications.

Designed for High-Volume and One-Off Projects

Whether customers need a single prototype or a full production run, ASF’s laser cutting setup is built to handle both efficiently. High-speed cutting combined with nesting software helps minimize material waste and reduce cost per part, even on smaller jobs.

Laser cutting is ideal for contractors looking for quick-turn parts, architects needing samples, or project managers coordinating multiple scopes of work.

Partner With ASF for Precision Metal Fabrication

ASF’s laser cutting capability is part of a broader commitment to technology, quality, and fast turnaround. By adding this machine to its lineup in 2026, ASF is better equipped to serve projects of all sizes throughout Connecticut and beyond.

Contact ASF today to learn more or to request a quote for your next project.