Tips To Reduce Your Metal Fabrication Expenses

With thoughtful planning, you can save a lot of money on your next metal fabrication job without sacrificing quality or style. Use these tips to reduce your metal fabrication expenses .

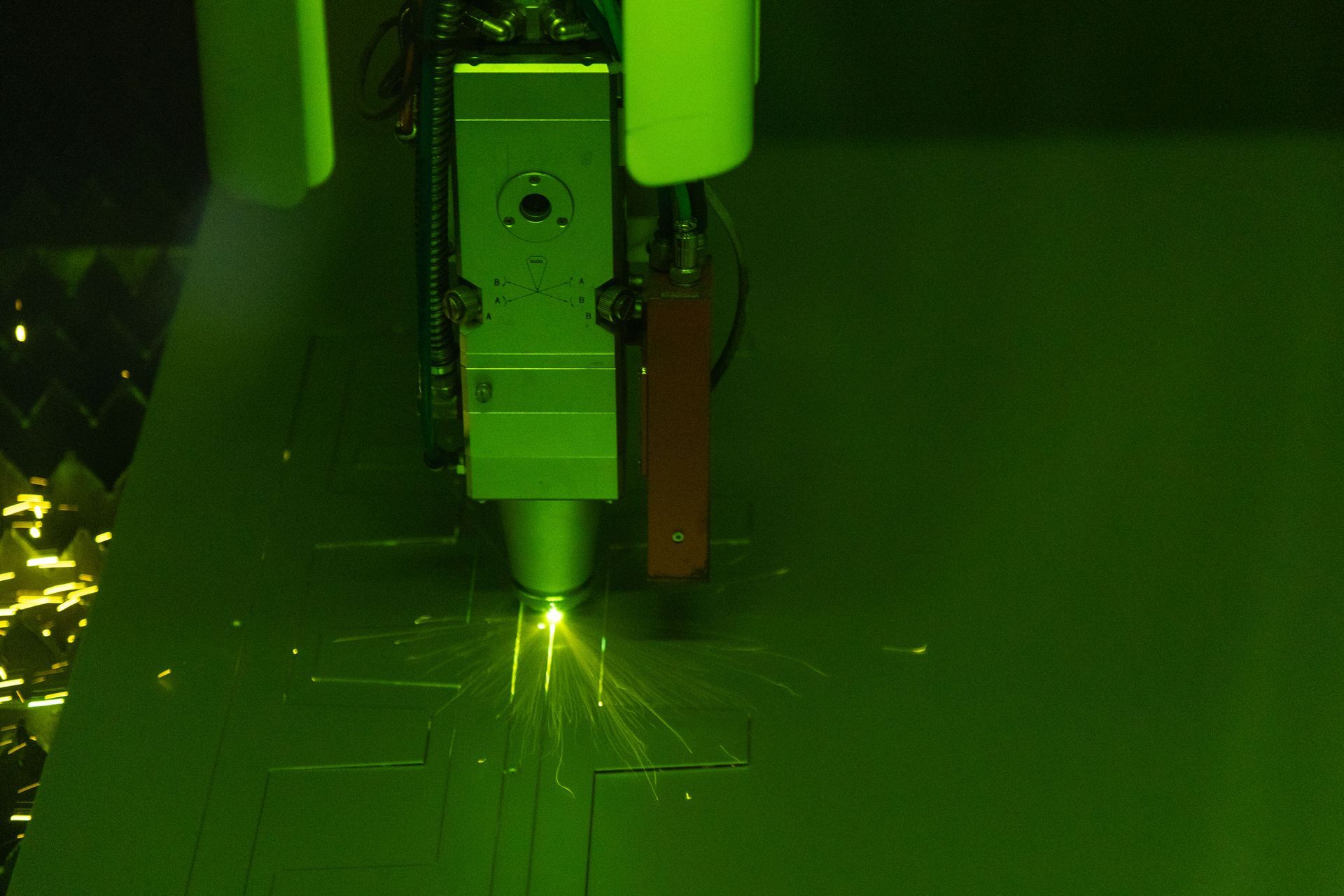

1. Work With an Experienced Fabricator

A skilled fabricator has practical experience and knowledge of metals and fabrication processes. Their expertise can help you save money and time while creating quality work.

Working with an experienced fabricator means you can rely on their skills for your project. They can suggest cost-saving modifications, simplifications, and material alternatives that might not be on your radar. And experienced fabricators have a wealth of specialized tools for the job.

2. Modify the Design

Another tip for reducing metal fabrication expenses is to incorporate cost-effective geometry in your designs. The more unique the bends for your project, the more machining and labor you need to create the part, which increases costs.

Fortunately, small changes can make a substantial difference in cost. A well-established fabricator has standard tools for achieving a variety of bends, so you can create a quality design while spending less. When you have some flexibility in your sheet metal design, you can make changes so that your order requires less tooling, saving money and time.

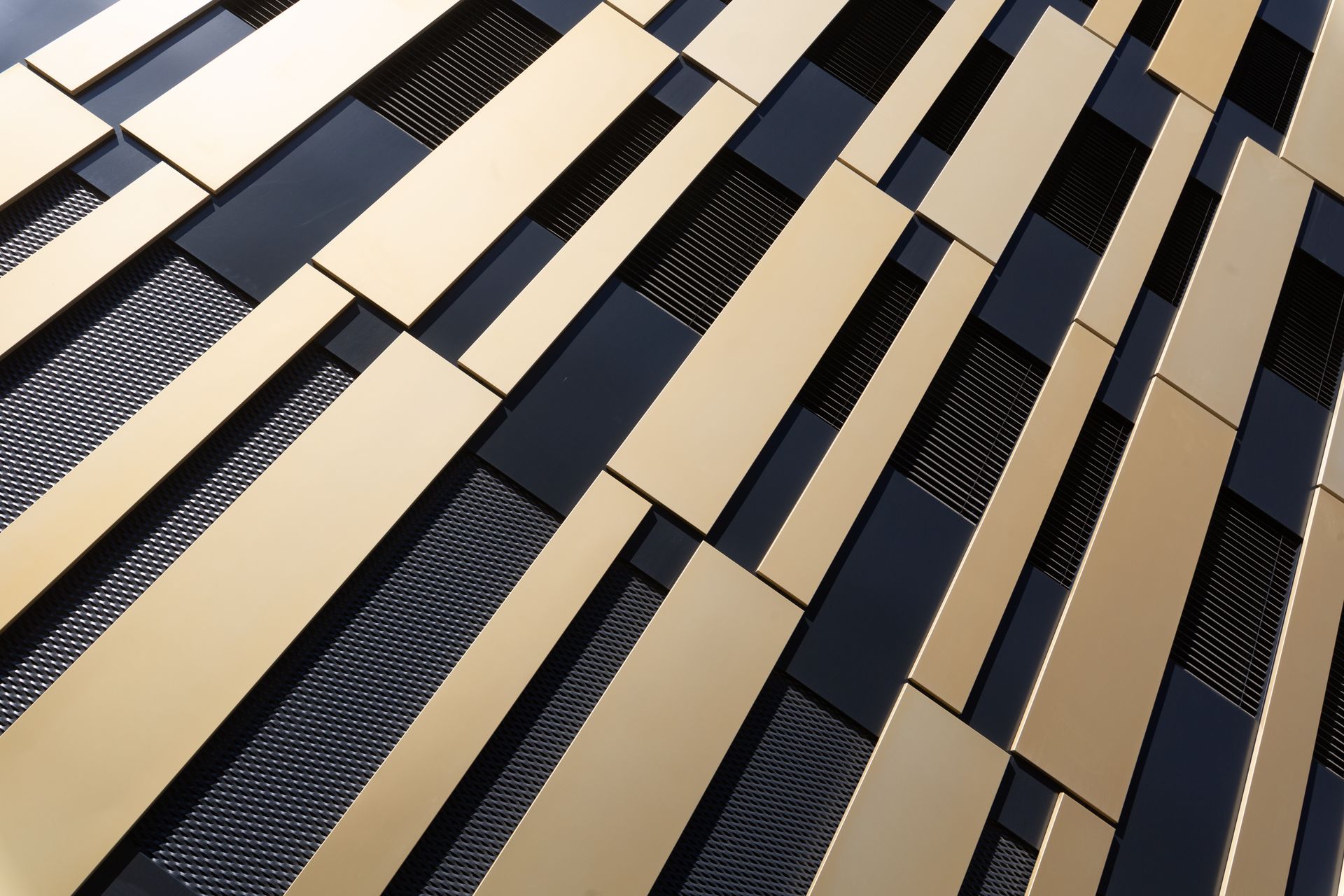

3. Choose the Right Material

Each material has properties that make it more or less suitable for end-use applications, and your selection of materials determines forming possibilities. So choosing the right material can help you save costs on metal fabrication upfront and repairs and maintenance down the line.

Steel, stainless steel, galvanized steel, copper, and aluminum are among the most popular metals. Thicker materials might restrict the cuts or bends the fabricator can achieve. Also, keep in mind that standard sheet metal sizes are typically lower in price than special lengths.

Hire Architectural System Fabricators for exceptional sheet metal bending services. We take pride in our friendly customer service and will work with you to ensure you receive quality metal products at the right price. Contact us today.