2026 Architectural Metal Trends: What Contractors and Architects Should Expect This Year

As the construction industry continues to prioritize performance, durability, and modern design, architectural metal remains a top choice for exterior and interior applications. In 2026, contractors and architects can expect continued demand for custom fabrication, cleaner aesthetics, and fast production timelines. Explore the key trends shaping architectural metalwork this year, and how ASF is positioned to support them.

Increased Use of ACM Panels in Building Envelopes

Aluminum composite material (ACM) panels continue to grow in popularity for commercial façades and wall systems. Lightweight and durable, these panels offer clean lines and smooth finishes that suit both modern and traditional designs.

ASF fabricates ACM panels from top brands like ALPOLIC and ALUCOBOND, with capabilities to route, fold, and prepare panels for installation. Contractors rely on ASF for precise fabrication and fast lead times, especially for large-scale commercial builds.

Custom Profiles and Long-Fold Capabilities

Architects are pushing for sleeker designs and longer uninterrupted panel runs. ASF’s long-folding machine — the only one of its kind in Connecticut — enables fabrication of metal components over 20 feet in length. This allows for longer trim pieces, copings, and cladding elements with fewer seams.

Custom profiles continue to be in high demand for detailing, water management, and unique visual features. ASF forms components in a wide range of metals, including aluminum, copper, zinc, and stainless steel.

Mixed-Material Wall Systems

Designers are combining materials like fiber cement, metal, and wood-look panels to create contrast and texture. ASF supports this trend with CNC routing for fiber cement panels (such as EQUITONE), as well as cutting and shaping of HPL, ACM, MDF, and other architectural surfaces.

By offering CNC routing and panel fabrication in-house, ASF reduces coordination issues and speeds up delivery.

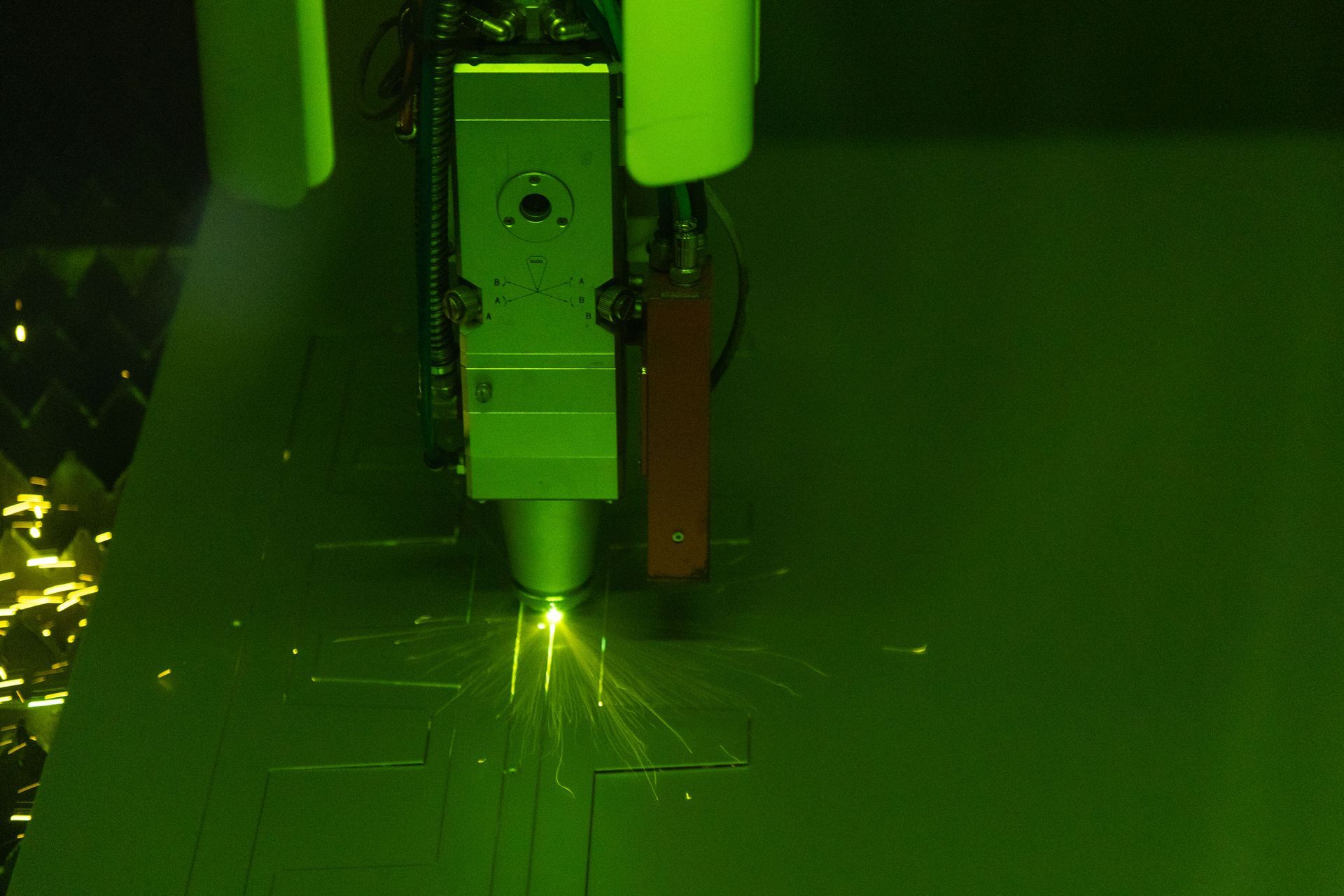

Faster Turnarounds With In-House Services

With project schedules tightening across the board, fabricators who can keep production in-house have a clear advantage. ASF’s investments in coil processing, laser cutting, and brake forming reduce reliance on outside vendors.

This means customers can expect shorter lead times, greater flexibility, and more control over last-minute design adjustments.

Focus on Performance and Longevity

Durability, weather resistance, and low maintenance continue to drive material choices. Pre-finished metals, factory-applied coatings, and post-painting options allow architects to specify materials that meet both performance and aesthetic requirements.

ASF works with customers to select materials that suit the environment and long-term needs of each project.

Partner With ASF for 2026 Projects

From precision-fabricated panels to complex trim profiles, ASF delivers architectural metal components built for today’s design and construction demands. Whether you’re managing a commercial façade upgrade or a ground-up build, ASF has the technology and experience to support your 2026 projects.

Contact us today to discuss your next project or request a quote.