5 Things To Look For When Contracting a Metal Fabricator

The right metal fabricator can help you create high-quality, durable products that meet your needs and exceed your expectations. Here are five things to look for when contracting a metal fabricator.

1. Expertise

The fabricator’s expertise is their expert skill and knowledge regarding manufacturing sheet metal products. Work with a company that has a proven record of delivering high-quality products.

A fabricator with expertise will apply their knowledge to your order. They can use the best processes, thoroughly answer your questions, and thoughtfully handle unexpected challenges.

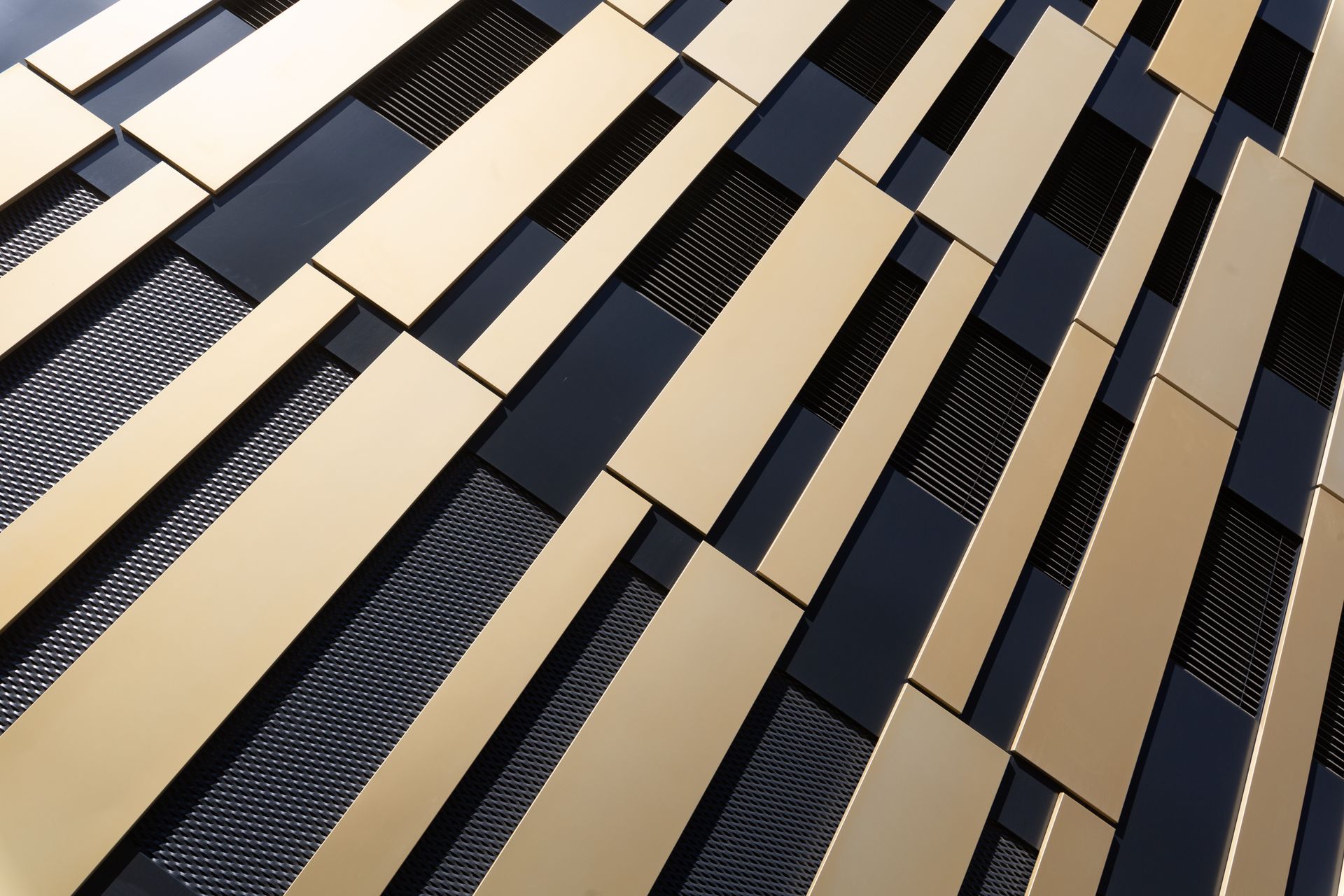

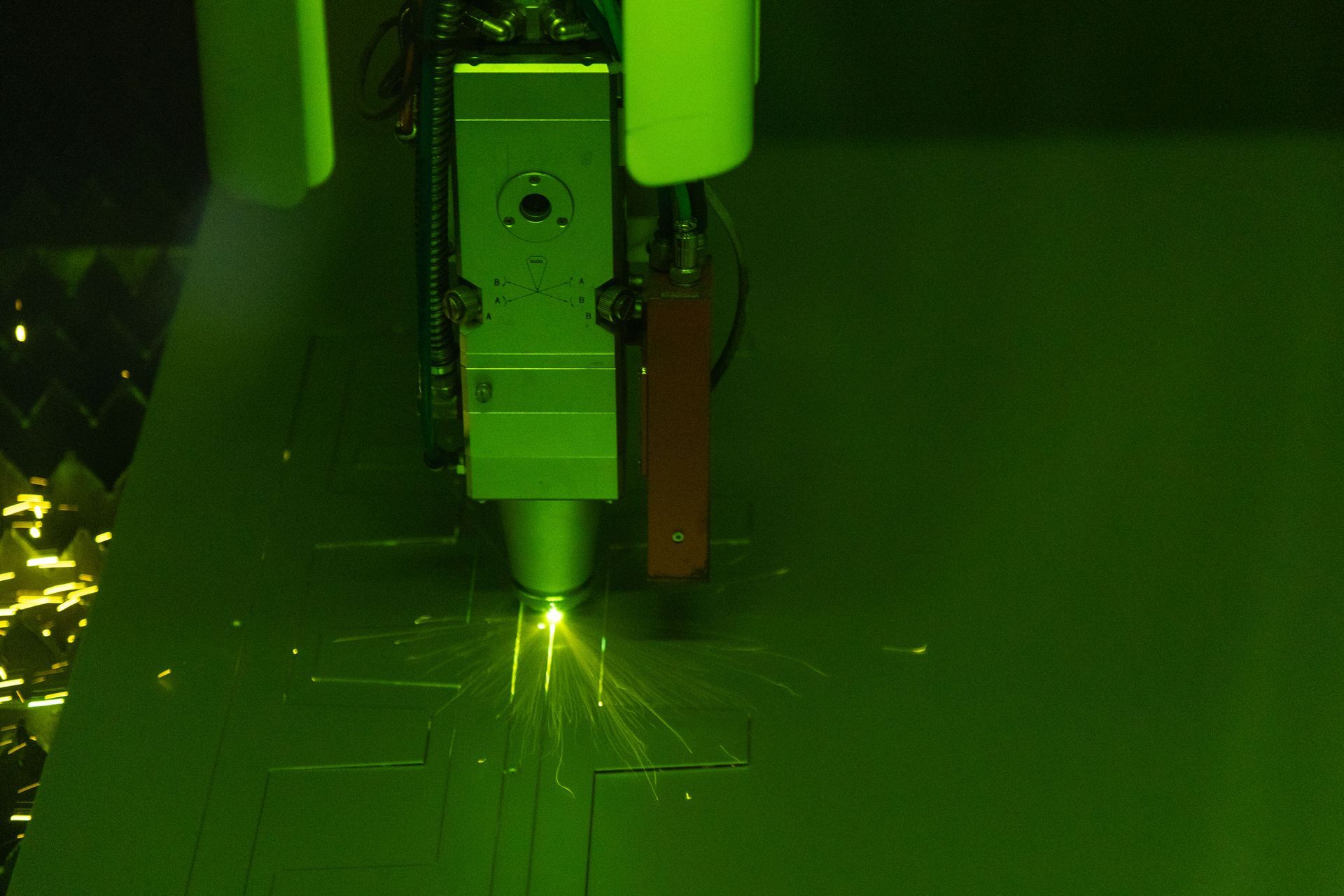

2. Equipment and Capabilities

Another important factor to consider is the fabricator’s capabilities, which come from their expertise and equipment. Depending on your project, you may need a fabricator with specific machinery to handle your materials or design.

Fabricators can use various machines to cut, bend, and assemble sheet metal and other flat metals. The devices affect the metalworker’s ability to achieve your designs and how precisely and efficiently they can do so.

3. Quality Control

Quality control is critical when it comes to metal fabrication. Quality control is the process the fabricator uses to ensure their products meet specifications.

Quality control helps avoid safety and reliability issues and keeps the fabricator on time and within budget. Before partnering with a company, ask how they control the quality of their fabricated metal.

4. Communication and Customer Service

Clear communication is another thing to look for when contracting a metal fabricator because it’s an important customer service component. The fabricator should provide regular updates on the status of your project.

A fabricator who provides great customer service will answer all your questions. And they’re willing to work with you to find cost-effective solutions that won’t sacrifice quality.

5. Reputation

Finally, check the company’s reputation to understand the experiences other businesses have had. A fabricator with a strong reputation for quality work and customer service will meet your expectations.

Looking at online reviews is usually the easiest way to check a fabricator’s reputation. You can also ask if the company has references you can contact directly.

Architectural System Fabricators is an experienced, reputable metal bending company in New England. Request a free quote today via our contact page, email, or phone.