What Are CNC Machines and How Do They Work?

Manufacturers who create components from metal, plastic, wood, ceramic, and composite materials use computer numerical control machines, commonly called CNC machines. CNC machines combine the precision of computers with the power of machining devices. Read on to discover what CNC machines are and how they work .

The Basics of CNC Machines

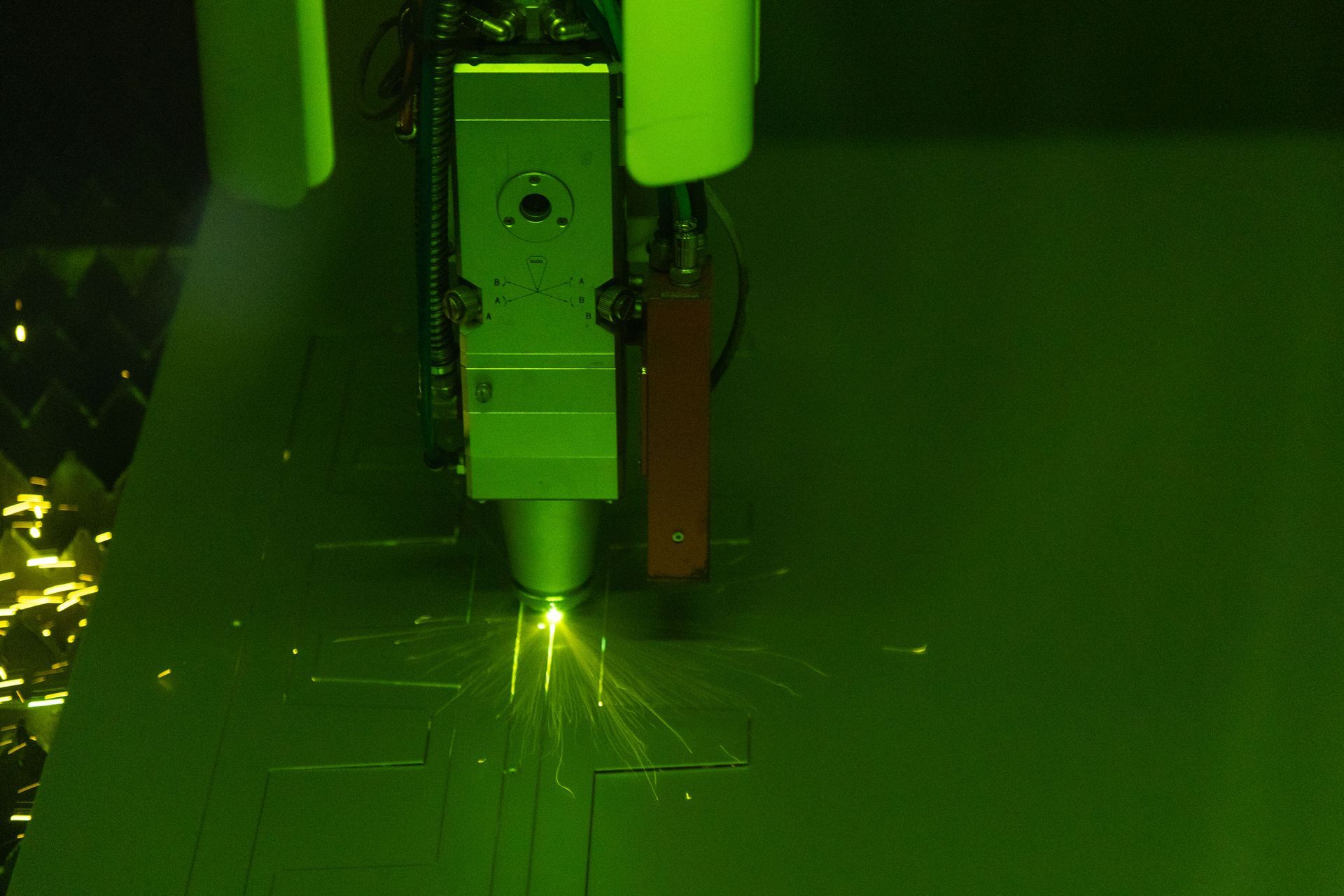

A CNC machine uses a computer to control machining tools such as drills, lathes, and grinders. The computer controls the motorized movable tool and, if one is present, the CNC’s motorized movable platform.

The device processes material based on programmed specifications. CNC machines can process materials without the direct control of a manual operator. However, operators must ensure they program the right specifications into the machine.

Programming Methods

Geometric code (G-code) is a programming language for CNC machines. G-code commands instruct the machine on how to move and what speed to move at. M-code controls miscellaneous functions, such as changing pallets. Other commands control other processes, but G-code and M-code are the primary programming languages used to control CNC machines.

There are three programming methods: manual, conversational, and computer-aided manufacturing (CAM) programming. The best type of programming method depends on factors like the operator’s programming knowledge, the geometry of the machined products, and production volume.

Benefits of CNC Machines

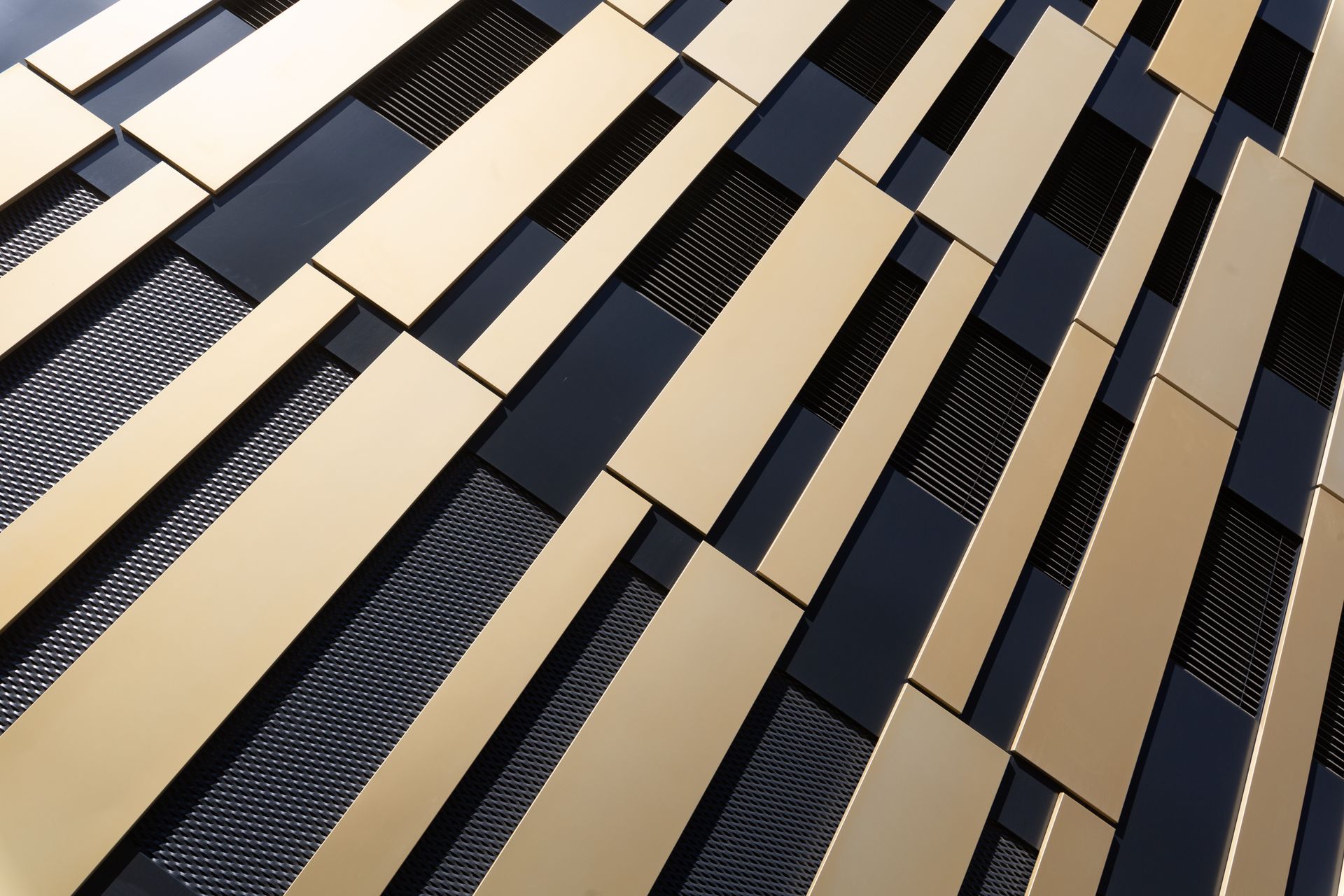

CNC machines are essential for manufacturing components used in a wide range of machines. The medical, aerospace, electronics, and transportation sectors are just a portion of industries that rely on CNC machining.

CNC machines move and cut materials precisely. The process minimizes waste, creates accurate components, and improves production efficiency. This tool helps save time and money on machining, benefiting manufacturers and their clients.

Learning about CNC machines and how they work gives you insight into modern-day fabrication processes. Architectural System Fabricators provides high-quality sheet metal fabrication services , including CNC routing for aluminum composite panels. Contact us today for a free quote or to learn more about our services.