The Most Common Techniques for Bending Sheet Metal

When metal fabricators bend sheet metal, they change the shape of a metal sheet into a desired form. This manufacturing process prepares metal for use in a final product. Learn about the most common techniques for bending sheet metal.

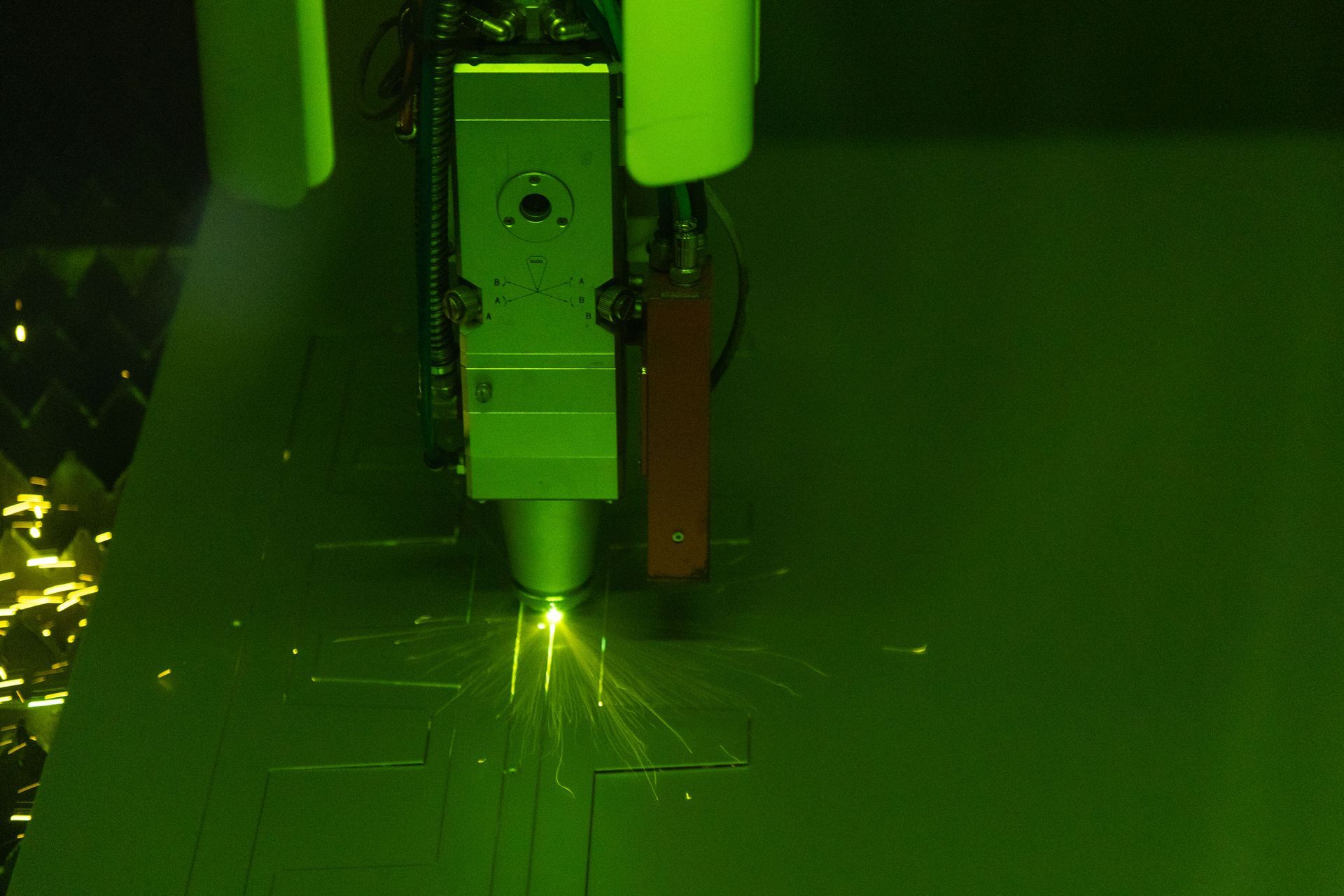

V-Bending

The most common way to bend sheet metal is through v-bending. The fabricator uses a die with a V-shape cut into it. They place the sheet metal over the die and use a V-shaped punch to press into the metal and bend it. This method can create acute, obtuse, and 90-degree angles, depending on the punch and die.

V-bending has three subset methods: bottoming, air bending, and the least common method, coining. U-bending is like V-bending and uses a punch and die to produce a U-shaped curve.

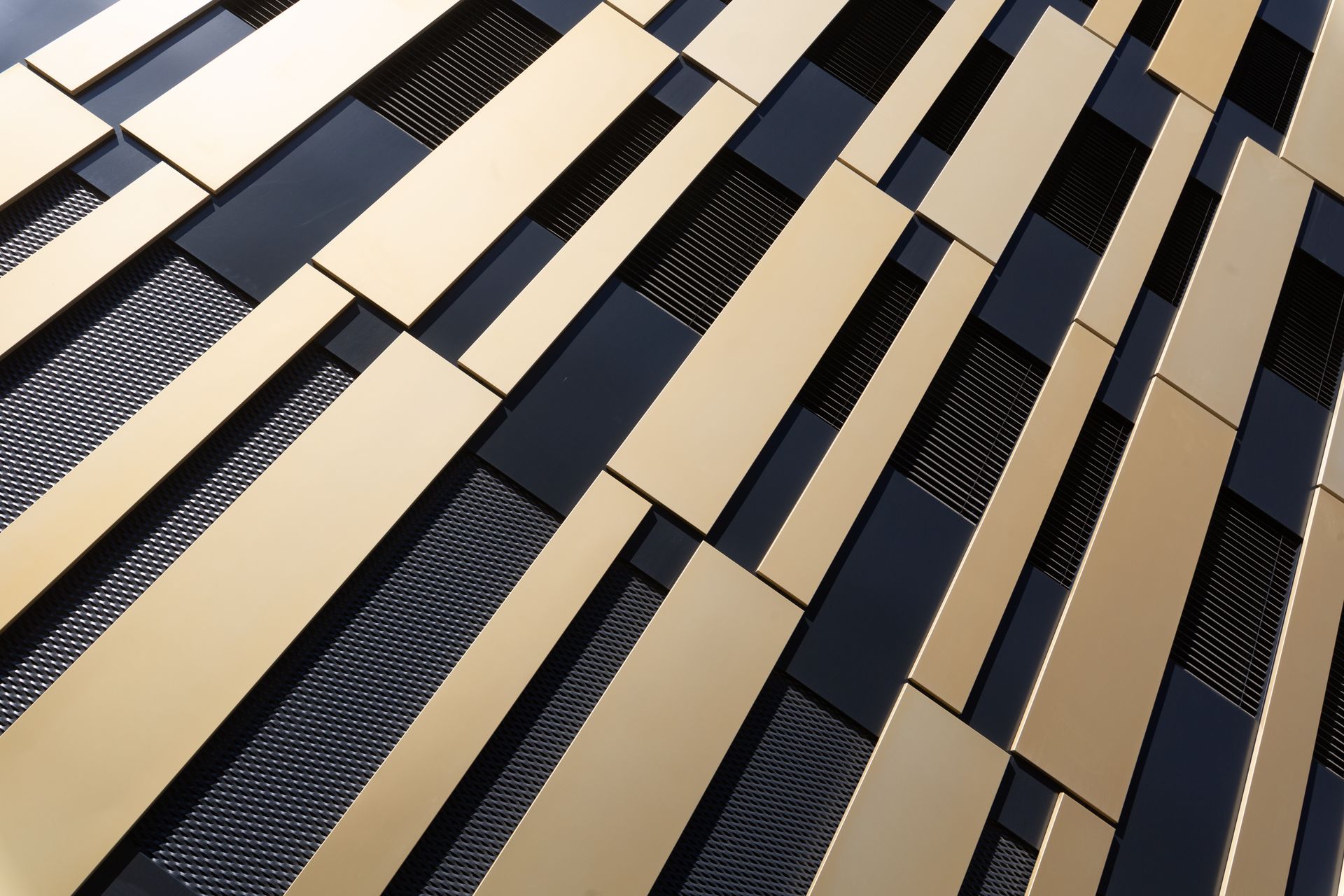

Roll Bending

Another common technique for bending sheet metal is roll bending. Fabricators use this method to bend metal into curved shapes such as cones, rolls, and cubes. Roll bending uses a set of adjustable upper rollers and lower rollers to create different dimensions in the metal.

The fabricator places the metal sheet between the rollers, which feed and bend the metal. This process is ideal for curving very long sheet metal parts.

Rotary Bending

Fabricators use rotary bending when they need to bend sheet metal at more than a 90-degree angle. The punch is a rotating cylinder with a v opening cut into it. The sheet metal lies on an anvil, and the rotary die pushes the sheet down over the edge of the anvil and makes the bend.

This process can bend metal as much as 120 degrees. Since rotary bending requires less force than wipe bending, this method can efficiently produce long and large heavy-gauge parts.

Edge Bending

Sometimes, fabricators want to bend just the edge of the metal. For edge bending, they place the sheet metal with a portion of the metal hanging over the edge of the lower die. A pressure pad over the sheet metal holds the metal in place.

A wiping die applies force to the end of the metal projecting over the edge of the die. The die pushes the metal, and it bends over the edge of the die. This process can create edge metal parts for roofing projects, such as a drip edge that supports the first row of shingles.

Let the experienced professionals at Architectural System Fabricators complete metal forming services for you. The type of metal bending process you need for your project depends on your desired metal geometry, the properties of the metal, and the product volume. Call us today for a quote!