3 Ways To Reduce Operation Costs Using Metal Fabricators

Metal fabrication can be an expensive process that requires a lot of time, precision, and skilled workers. Due to the work’s complexity and the expertise of fabricators, metal fabrication can cost a company a small fortune. Knowing three ways to reduce operation costs of using metal fabricators can save a business unnecessary expense while retaining the same level of product quality.

Invest In the Most Appropriate Materials

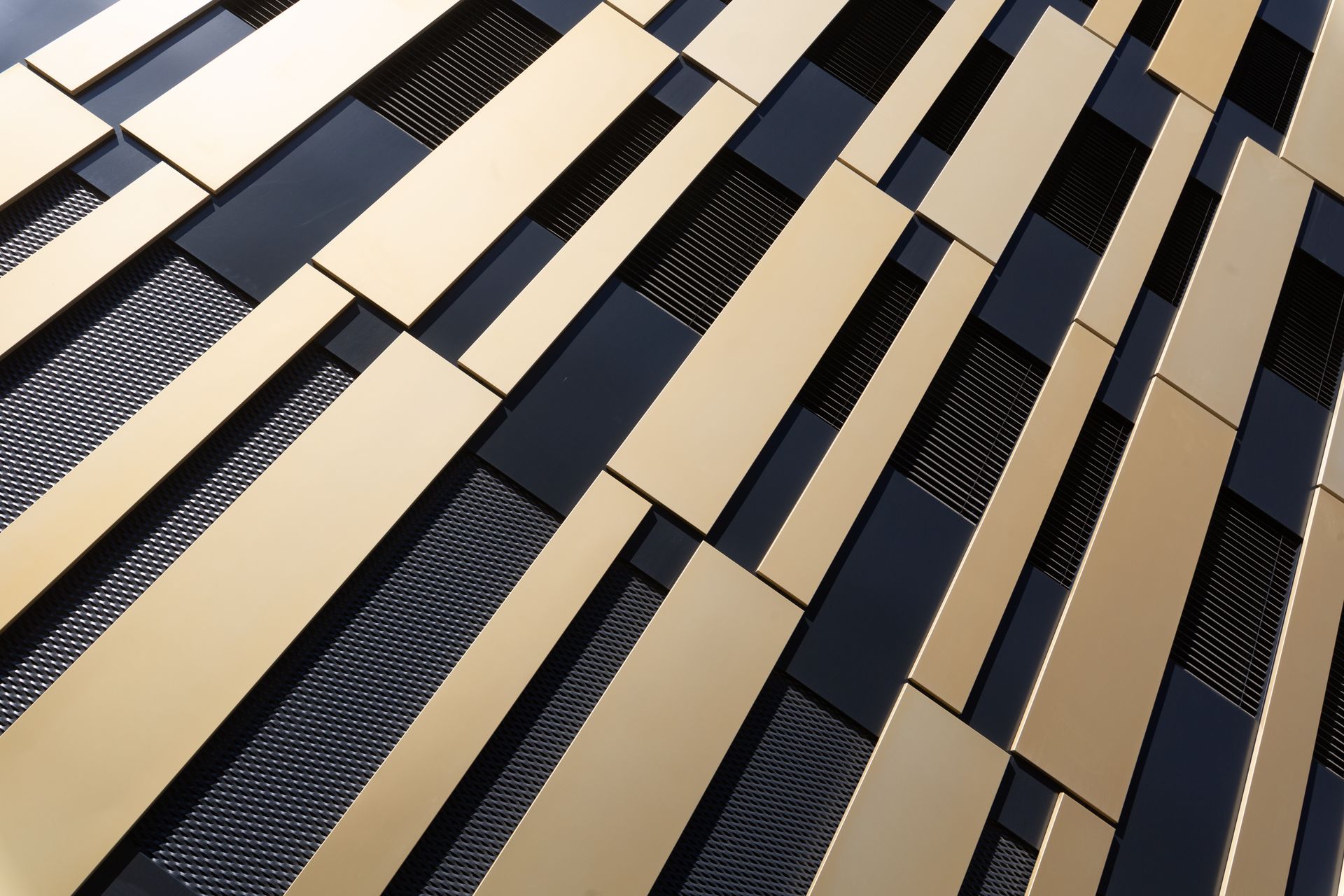

A company can use a wide variety of different materials on their products such as stainless steel, ACM, copper, or aluminum. Each metal has certain properties that can make it ideal or challenging to work with, and each one comes with its own cost.

You must be aware of these advantages, challenges, and pricing when procuring materials. Weigh your options. Going with the less expensive alternative doesn’t necessarily harm your final product’s quality, but it can save you and your company money.

Streamline Your Designs

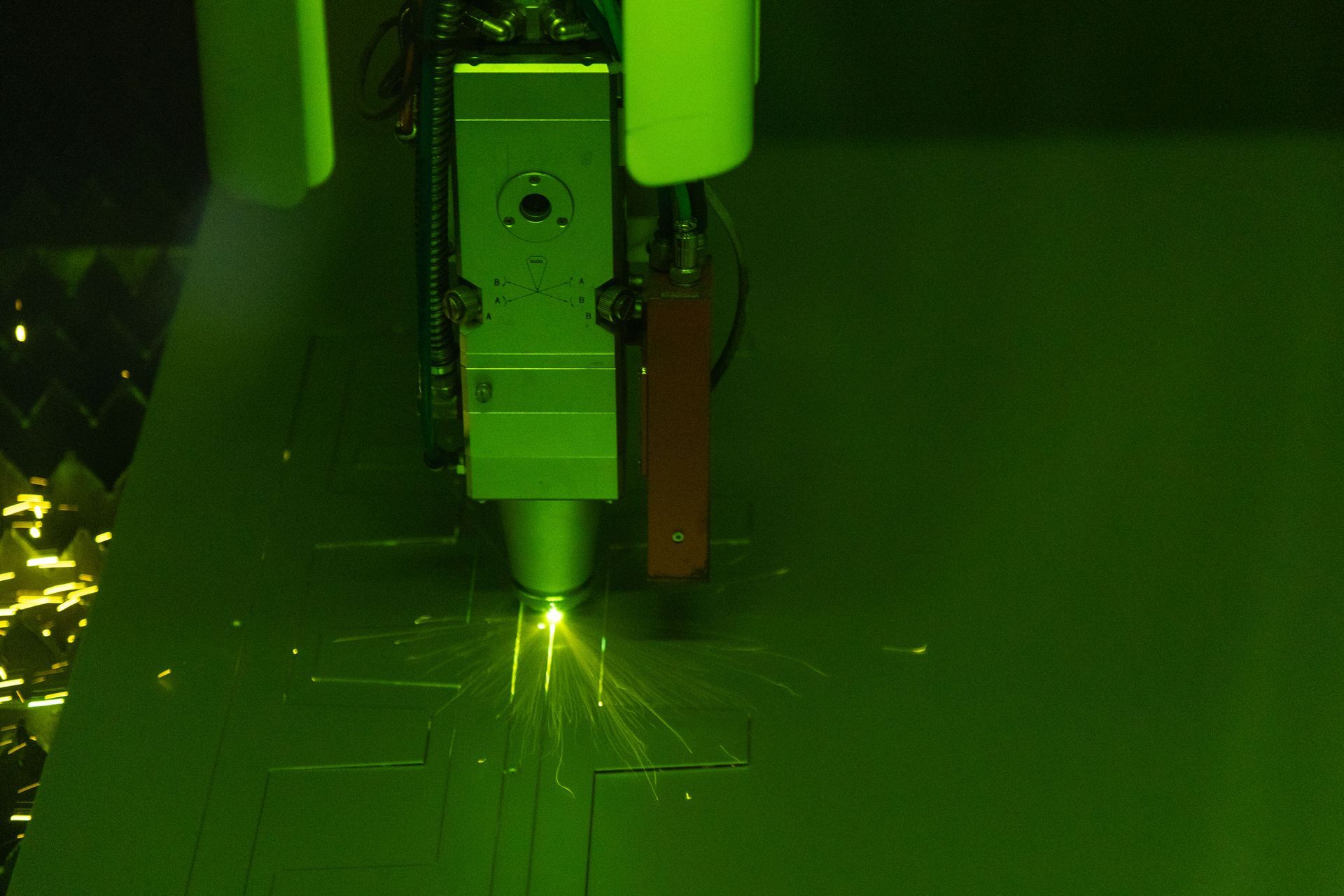

Designers often create intricate and interesting designs, but they aren’t always feasible when manufacturing them. Complex designs can cause production to drag out longer, require specialized equipment, and can demand more expensive metal.

The time and cost of creating these pieces can hit your company hard in two ways: the first, the obvious expenses of manufacturing intricate pieces. Second, you could alienate customers due to rising prices. Streamline your designs and make them practical, efficient, and high-qualit

Partner With Third-Party Companies

When a single company needs to deal with all the aspects of metal fabrication, it can become too great of a burden. The process requires a wide variety of skilled workers, specialized machinery, and floor space. The costs add up quickly.

By partnering with a third-party ACM fabricator, you can significantly cut down on the expense of keeping everything in-house. Outsourcing certain processes can take a major strain off your company and your workers, serving as a cost-effective option without sacrificing your product’s quality.

Improve Profitability

It’s necessary to know several ways to reduce spending on your metal fabrication so you can increase profits. It’s a difficult balancing act, but spending less money to create the same product doesn’t mean diminishing its value or lessening its quality. Search for ways to save your budget and use those saving to further improve your processes.