Press Braking vs. Roll-Forming: Key Things To Consider

Press braking and roll-forming are distinct processes for bending metal. Choose between the two to complete your metal fabrication project with the best balance of cost, time, and efficacy.

While both methods yield quality results, consider their strengths and limitations in terms of your project needs. Read about these key things to consider about press braking vs. roll-forming.

Compare How Each Machine Works

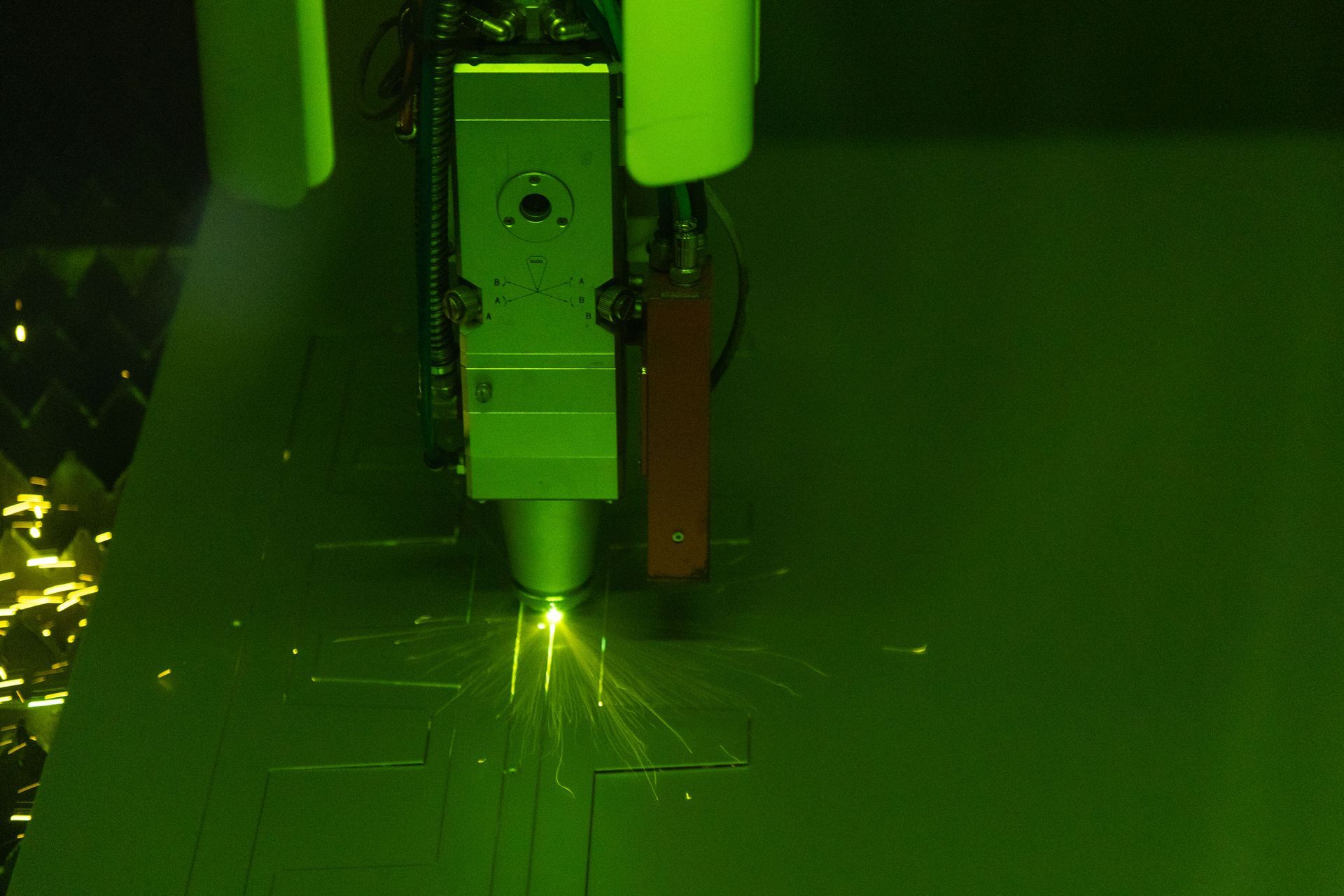

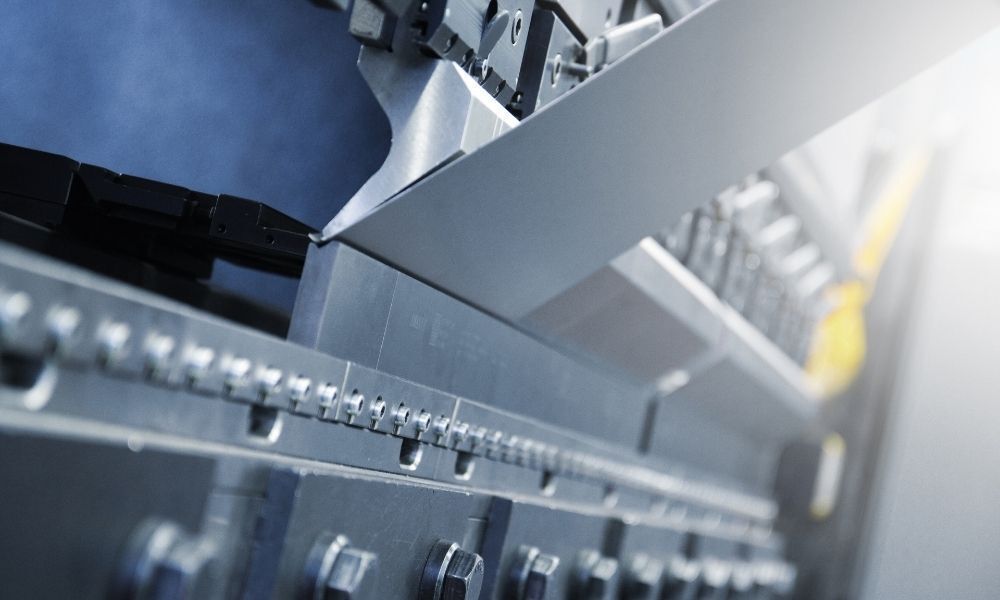

Press braking uses a press brake to hold the metal along an axis, then a thin blade (the punch) bends the metal by pressing it into a frame (the die). Different punches and dies curve the metal into different shapes. The metal sheet doesn’t touch the die to make a rounder bend. For sharper edges, direct contact between the metal and the frame causes a crease.

With roll-forming, a set of rollers organized in pairs rest one on top of the other. The machine pushes the metal through the rollers in a continuous pass. Each roller has a different shape, and the rollers press against each other to bend and shape the metal.

Consider the Shape and Size of the Metal

The shape and size of the metal you want to bend affect the process you should choose. The press brake works on individual sheets of metal. The width of the press brake limits both the sheet size and bend length that the machine can handle.

Roll-forming is better at handling longer lengths of metal than press braking. The roll-form works with a continuous coil of metal rather than individual sheets. After rolling, cut the pieces to the desired dimensions. There is no limit to the length of the bend.

Account for Project Volume

Your project’s volume run is a key thing to consider about press braking vs. roll-forming because it affects the efficiency of these processes. Press braking is generally more affordable than roll-forming, and it’s better for small- to medium-volume projects.

As roll-forming progressively bends metal in a single pass, it can move quickly. But when you need to change the bends you’re creating, you have to recalibrate the rollers. That’s why this process is better for large-volume projects. The larger the volume, the less each piece will cost for labor and setup.

Choose ASF

At Architectural Systems Fabricators, we pride ourselves on providing the best metal forming services. We create products for commercial roofers, siding contractors, masons, glaziers, garage door producers, business owners, and residential roofers.