A Brief History of Metal Bending Machines

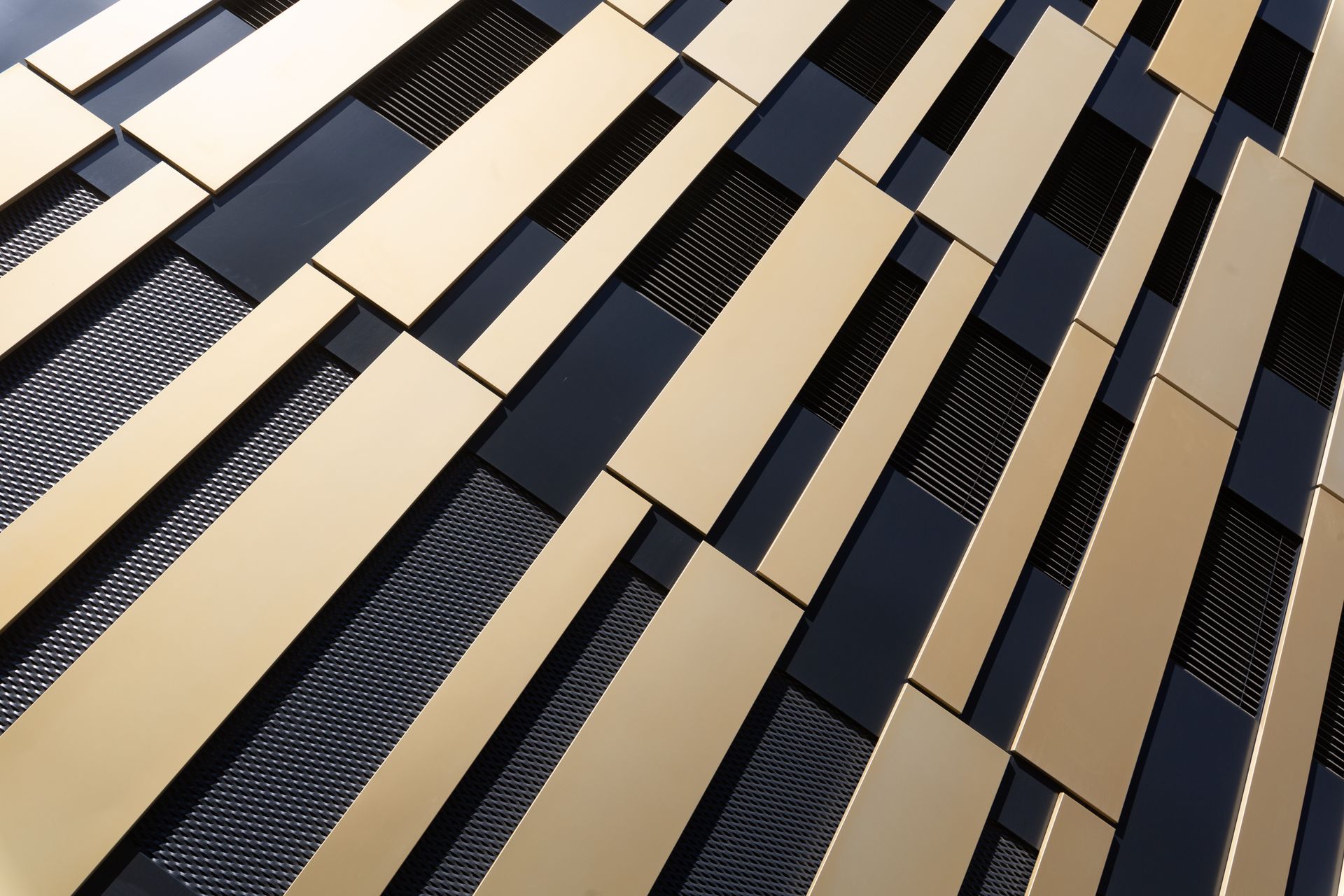

A metal bending machine forms metal pieces into diverse shapes including plates, strips, rods, tubes, and more. Metal bending machines shape metal for an array of products such as car panels, aircraft parts, cabinets, gutters, architectural features, and more.

Over time, we’ve discovered more uses for bent metal. This growing demand has prompted the evolution of metal bending machinery. Read this brief history of metal bending machines to learn more.

Shifting From Iron to Steel

In the past, curved metal structures were usually made from iron. Blacksmiths could curve small pieces of iron through hot forging because of the material’s softness. The blacksmith would take the workpiece (usually iron), heat it, and shape it through hammering and pressing.

While trip hammers were used in Imperial China hundreds of years before they appeared in Europe, blacksmiths in medieval Europe began using water-powered hammer forges in the 11th century. With this tool, they were able to create large quantities of steel sheets. This changed the metalworking field, resulting in the formation of specialty metalworking guilds.

The First Sheet Metal Bending Machine

During the 18th century, metal started replacing wood in metalworking equipment. This change in material, combined with a more sophisticated system of levers and controls, made metalworking easier. And just as the introduction of mass-produced sheet metal helped the industry take off, the invention of the reversing rolling mill at the end of the 18th century increased mechanical sheet metal production.

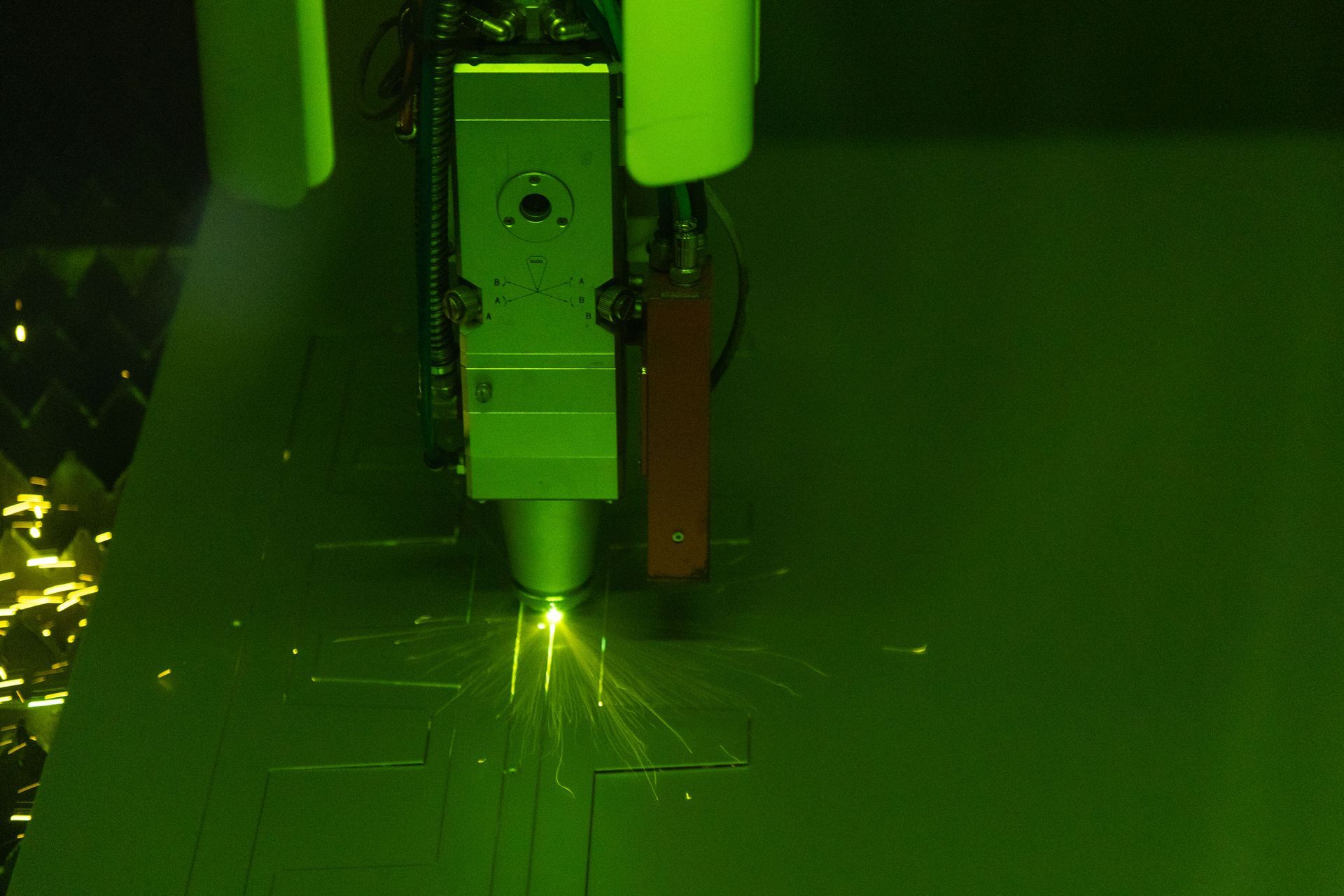

The first metal bending machines were made in the 19th century. With these machines, the locking lever and bending tools were powered by hydraulic cylinders and controlled with a lever valve. Eventually, the shears were also powered hydraulically.

20th Century

The twentieth century saw massive changes in the history of metal bending machines. Starting in the 1900s, bending systems became increasingly electrified. The first control systems operated clamping, bending, and cutting.

Numerical controls (CNC) for machine tools were developed in the 1970s. The operator could pre-set values for clamping, bending, and cutting. In the mid-1970’s, steel bending machines became capable of curving large steel beams accurately and at a much lower cost. This improved process led to an increase in curved steel in construction.

At the end of the 1990s, operators could use graphic control systems on their metal bending machines. Soon thereafter, operators could input values using touchscreens. CNC metal bending machines make the once extremely difficult tasks of metal-bending so much easier, allowing metal fabricators to create precisely bent parts for offices, airport terminals, mega stores, and much more.

Moving Forward

As in many other industries, metal bending machines are becoming increasingly automated, cost-efficient, and precise. Architectural System Fabricators provides high-quality metal forming services by using advanced metal bending machinery. Let us complete your next fabricating job!