Top Benefits of Using Aluminum Composite Panels

The material you choose for your construction project impacts the cost, labor, and time requirements. With this in mind, aluminum composite material (ACM) is an attractive option for indoor and outdoor applications.

ACM consists of three layers: two layers of aluminum that sandwich a non-aluminum core. Consider ACM for your next fabrication project. Learn the top benefits of using aluminum composite panels.

1. ACM Is Durable

ACM has good dimensional stability, so it will maintain its structural integrity. Once we fabricate a panel, it’s unlikely to change its shape due to the environment or wear and tear over time. The durability of ACM makes it a popular choice for installation on ships and for commercial and residential applications.

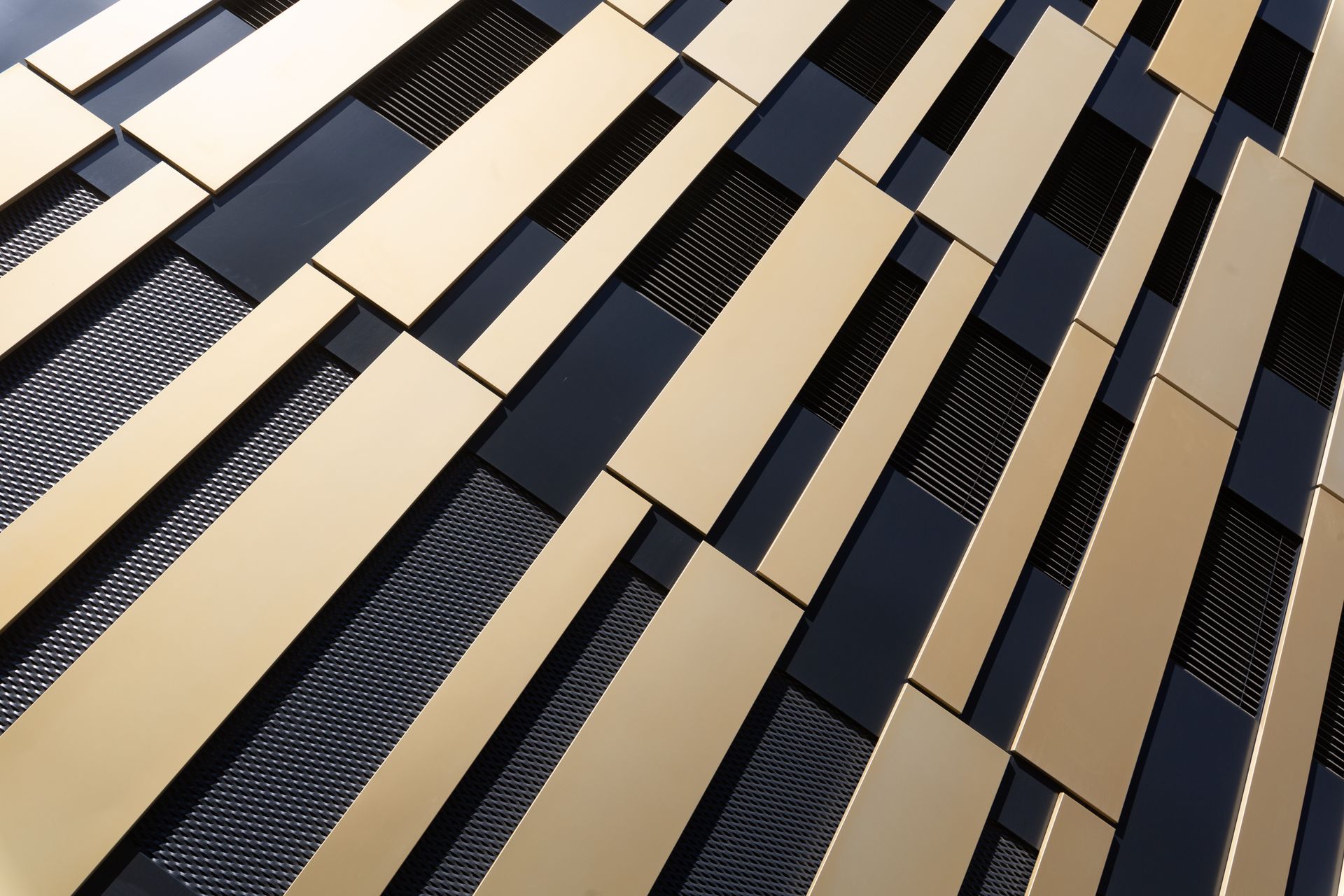

2. It Looks Beautiful

Another benefit of using aluminum composite panels is that they look beautiful. Choose from a range of colors and finishes that fit the style you want. Whether you want a sleek or matte design or something subtle or eye-catching, aluminum composite panels will work. And since this is a low-maintenance material that resists wear and corrosion, you can enjoy the design for a long time.

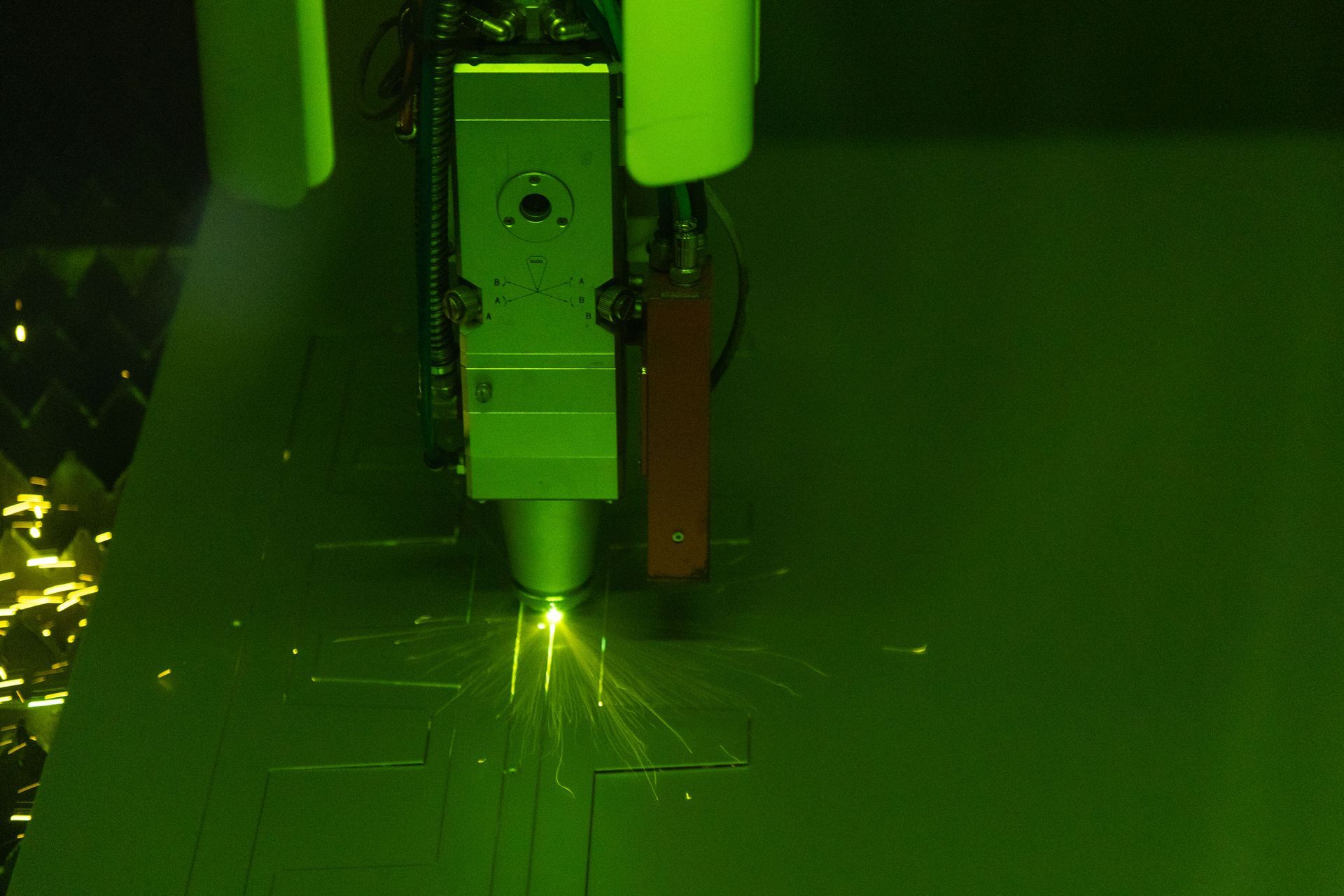

3. ACM Is Versatile

Aluminum composite material’s flexibility makes it a versatile construction piece. It can be punched, engraved, curved, or flattened. This characteristic makes it an ideal medium for creating interesting facades. If you’re interested in incorporating high-quality design into your project, make it happen with ACM.

4. The Material Is Lightweight

Aluminum is prized for being so lightweight, and ACM’s core is also lightweight. This makes it easier for everyone from fabricators to installers to work with this material. Lightweight materials provide a significant benefit for moving machines, such as automobiles. And transporting ACM panels costs less than it would if they weighed more.

5. It’s Easy To Install the Panels

Finally, installing panels at your site is simple. Because ACM is versatile, a professional fabricator can make precise forms. And because it’s lightweight and durable, construction workers can easily manipulate the piece into place without worrying about fragility. The easier the installation, the less time and money the process requires.

Get ACM From Architectural System Fabricators

Architectural System Fabricators works efficiently to deliver high-quality products. ACM panels are some of our top-requested offerings. If you need professional ACM fabricators, contact us today.