The Pros and Cons of CNC Routing Machines

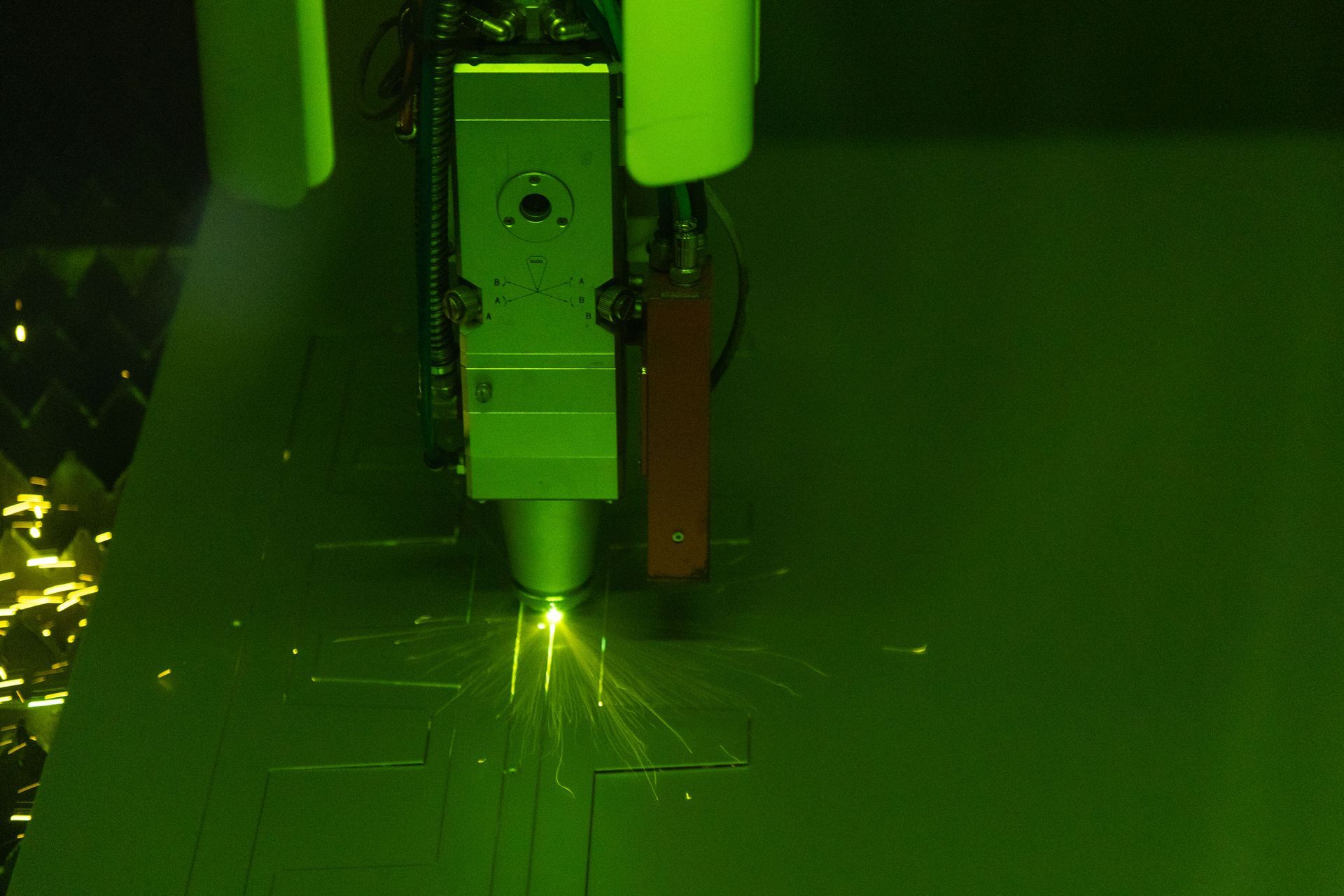

A computerized numerical control (CNC) routing machine uses software and code to cut, shape, and create parts from materials like plastic, foam, wood, and soft metals. Learn the pros and cons of CNC routing machines and consider using it for your metal fabrication needs.

Pro: Works With Various Materials

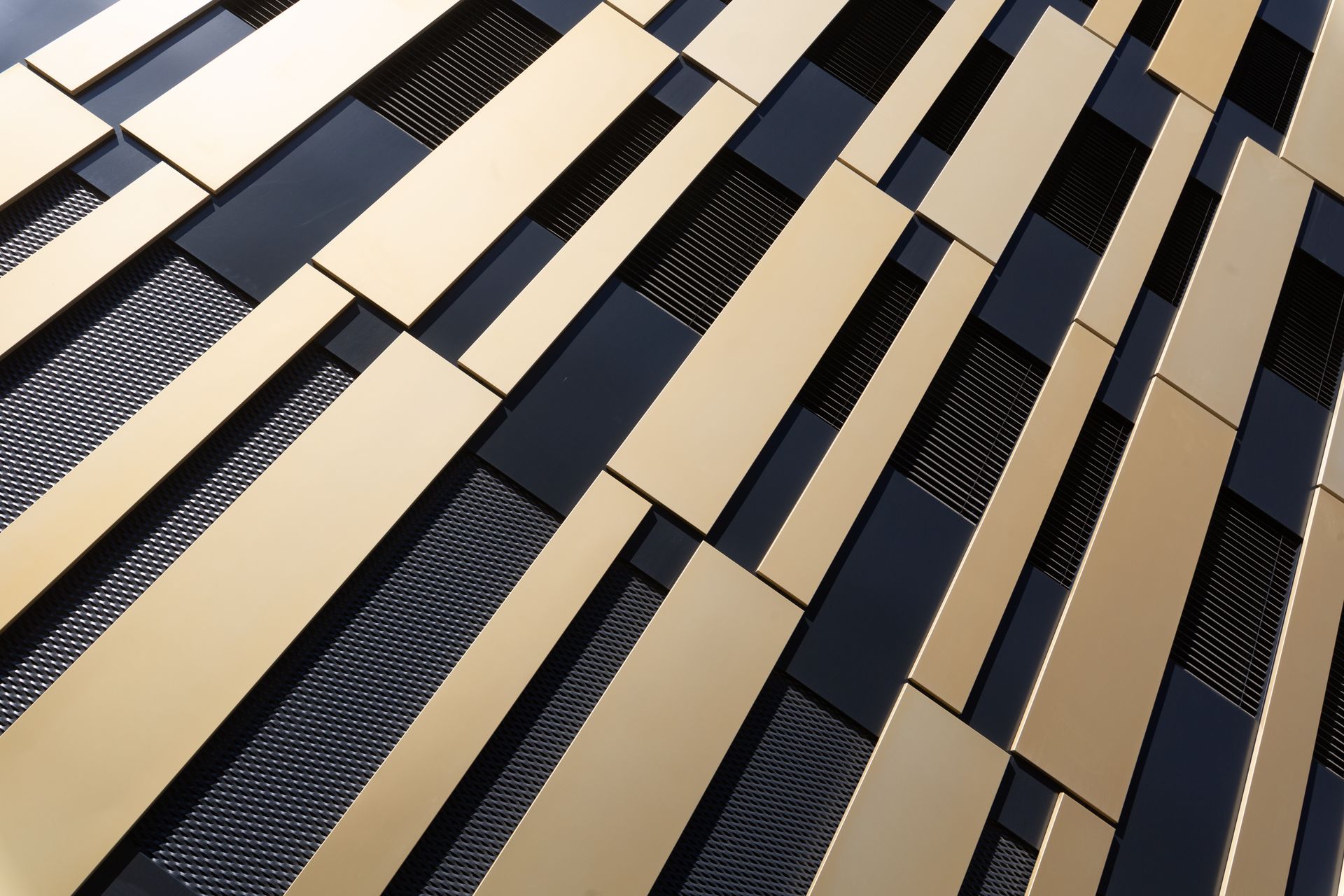

The CNC routing machine is a versatile piece of equipment that can cut many materials. CNC can cut and shape important construction materials such as ACM, acrylic, phenolics, and high-density polyethylene (HDPE), and more.

Pro: Reduce Materials Waste

Another pro of using the CNC is that it reduces materials waste. This lowers unnecessary costs, helping you to stay within budget. It’s also great for the environment because it reduces the need for materials and minimizes energy waste, too.

Pro: Fast Turn-Around

One of the best reasons to use a CNC routing machine for your project is that it makes quick, accurate cuts. The speed and precision of the CNC shortens production time. You get your finished material faster without compromising quality.

Con: Machining Cost (Possibly)

After considering so many pros of CNC routing machines, one of the possible cons of CNC machining is the cost. Discussing your project needs with the fabricator can help you balance costs, efficiency, and quality.

The fabricator can explain how factors such as machining time and the cost of materials influence the overall cost. A customer-friendly fabricator can also explain what contributes to the machining cost, such as cut complexity.

Con: Cost of Equipment

Finally, another possible con of the CNC relates to cost. Having an in-house CNC machine is costly. By partnering with a reliable fabricator, you avoid a large purchase and get to enjoy the benefits of CNC machining.

Work With Architectural System Fabricators

At Architectural System Fabricators, we’re happy to work with you to find the best solutions for your project. Our expertise as ACM fabricators can help you decide if CNC machining is for you. Contact us today for details.